Products Line

Home > Products Line > Ball Valve

Ball Valve

Parts and Material List

Design

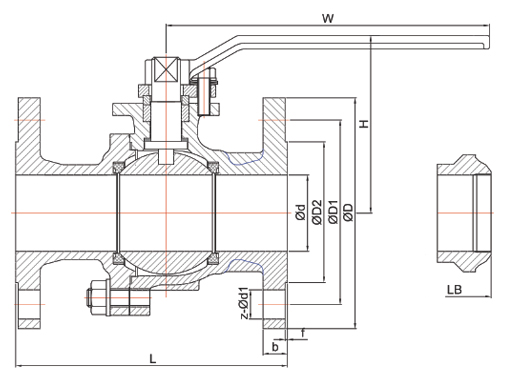

AVC ball valve are designed and manufactured to provide maximum service life and dependability. All ball valves are full ported and meet the design requirements of American petroleum Institute Standard API 6D, British Standard BS 5351 and generally confirm to American Society of Mechanical Engieers Standard ASME 816.34. Valves are available in a complete range of body/bonnet materials and trims.Applicable Standards

- Steel Ball Valve, API 608 /AP| 6D

- Steel Ball Valve, ISO 10434 / ISO 14313 Fire Durable, API 607

- Steel Valve, ASME 516.34

- Anti Static, API 608

- Face to Face, API 6D

- End Flanges, ASME 516.5

- Buttwelding Ends, ASME 516.25 Inspection and Test, API 598 /AP| 6D

Range of Materials

Standard body/cap materials include Carbon Steel Low Alloy and stainless steels. For special applications they can supplied in other grades of Alloy and Stainless Steel. There’s a full range of trim materials to match any service. Optional packing and gasket materials are available for a full range of service conditions.Design Description

- Full port design

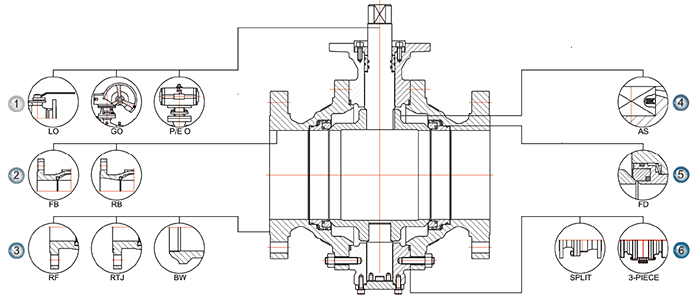

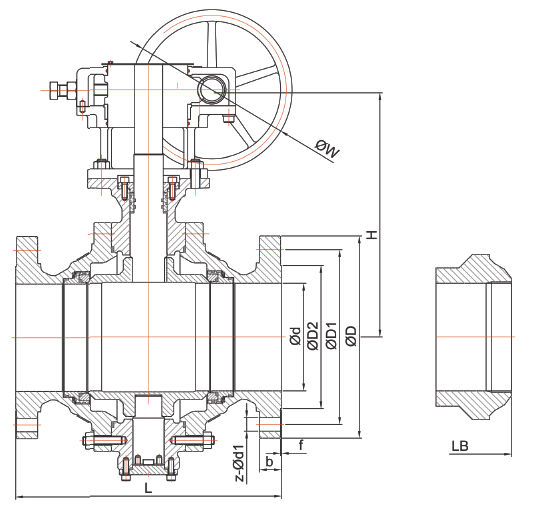

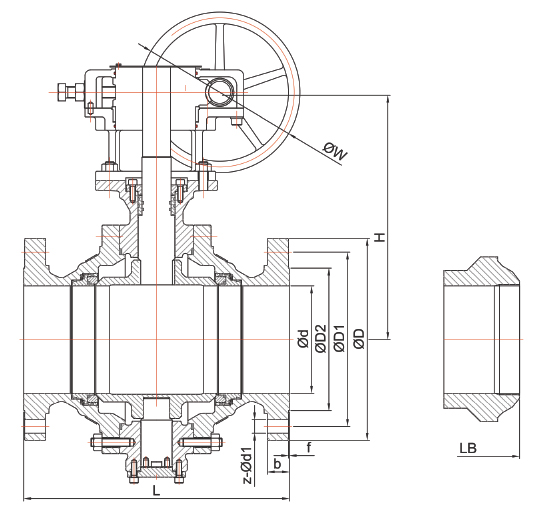

- BB, Bolted cap, split body

- Floating ball type

- Blow-out proof stem

- Fire durable construction

- Anti static device

- ISO 5211 Mounting pad

- Flanged 0r buttwelding ends

- Available with Worm Gear operator

-

Operating

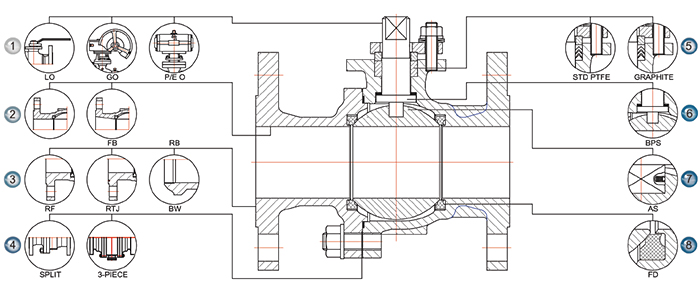

Extended lever for easy operation. Also available with gearing, motor actuators, pneumatic or hydraulic actuators for more difficult services. Bore

Full bore or reduce bore. Full bore design provides exceptional flow control.End Connections

A choice of flanged, RTJ flange or butt-welding end for piping flexibility.Body & Cap

Split or 2-piece, split body & cap for 12" & small. Disassembies easily for repair or replacement of internal components.Packing

STD packing multiple V-PTFE packing, combined with live loading, maintains packing compression under high-cycle and severe service applications. Graphite packing use suitable for high temperature.BPS

Blow-out proof stem. A pressure safe stern shoulder design that protects against failure under excess pressure.AS

Anti Static. A metallic contact is always granted between ball and .stem / body to discharge eventual statics build-up during serwce.FD

Fire durable. Designed to API 607 or BS 6755 to grant their operation suitability on case of fire. Secondary metal to metal seal acts as backup if primary seal is destroyed by fire. Valves ordered for compliance with API 607 will be provided with graphite packing and gasket.

Floating Type Ball Valve - Material List

|

||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

Note 2. Hard Faced (H/F) - Tungasten carbide. Chromium Carbide, Stellite or others materials.

Floating Type Class 150 LB

| ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

Floating Type Class 300 LB

| ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

Floating Type Class 600 LB

| ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

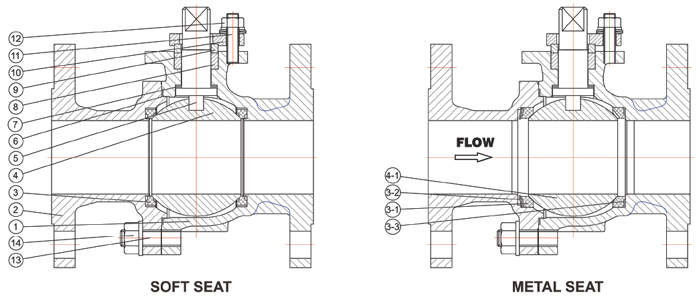

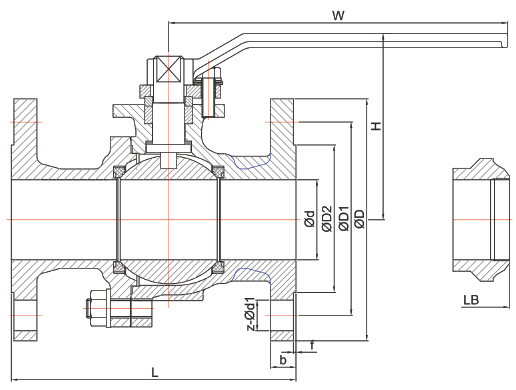

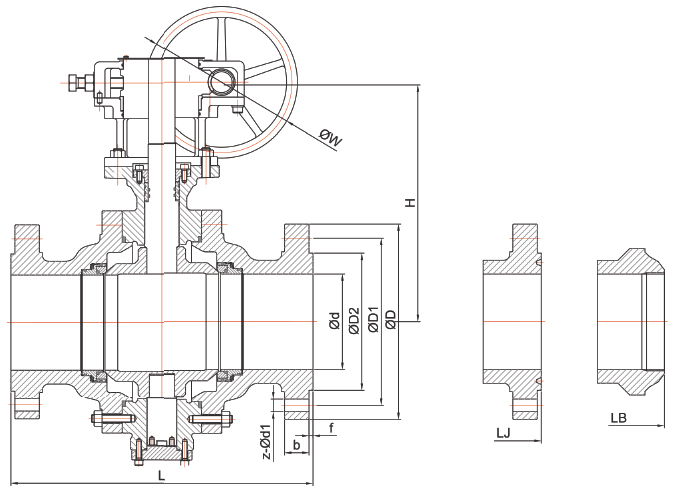

Trunnion Type, CS I SS IAS - Design

Design

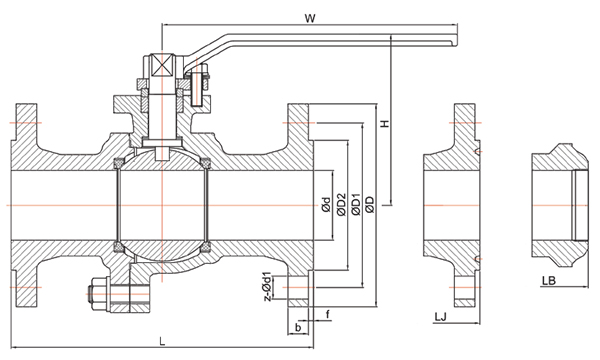

AVC ball valve are designed and manufactured to provide maximum service life and dependability. All ball valves are full ported and meet the design requirements of American petroleum Institute Standard API 608 & API 6D, British Standard BS 5351 and generally confirm to American Society of Mechanical Engieers Standard ASME 816.34. Valves are available in a complete range of body/bonnet materials and trims.Applicable Standards

- Steel Ball Valve, API 608 /AP| 6D

- Steel Ball Valve, ISO 10434 / ISO 14313

- Fire Durable, API 607

- Steel Valve, ASME 816.34

- Anti Static, API 608

- Face to Face, API 6D

- End Flanges, ASIVIE 816.5

- Buttwelding Ends, ASME 816.25

- Inspection and Test, API 598 /AP| 6D

Range of Materials

Standard body/cap materials include Carbon Steel Low Alloy and stainless steels. For special applications they can supplied in other grades of Alloy and Stainless Steel. There’s a full range of trim materials to match any service. Optional packing and gasket materials are available for a full range of service conditions.Design Description

- Full port design

- BB, Bolted cap, split body

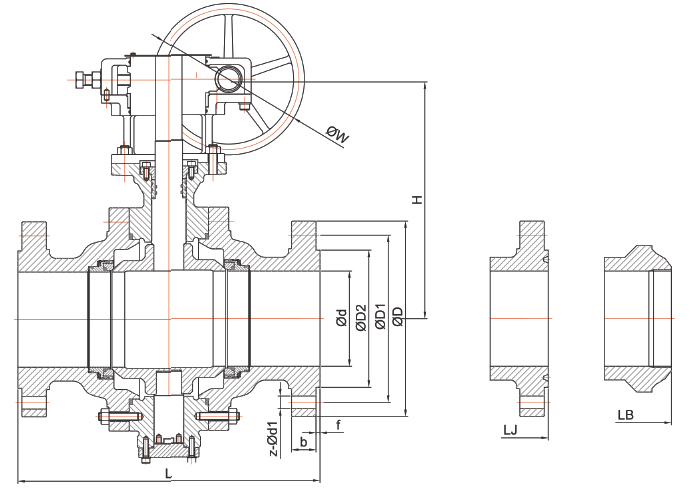

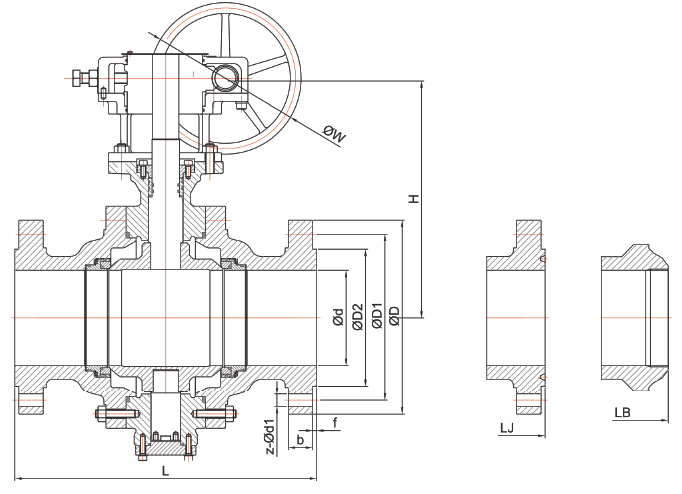

- 3-Piece body for 16" & above

- Trunnion mounted ball type

- Blow-out proof stem

- Fire durable construction

- Anti static device

- ISO 5211 Mounting pad

- Flanged or buttwelding ends Available with Worm Gear operator

Operating

Extended lever for easy operation. Also available with gearing, motor actuators, pneumatic or hydraulic actuators for more difficult services.Bore

Full bore or reduce bore. Full bore design provides exceptional flow control.End Connections

A choice of flanged, RTJ flange or butt-welding end for piping flexibilityFD

Anti Static. A metallic contact is always granted between ball and stem / body to discharge eventual statics build-up during service.FD

Fire Durale designed to API 607 or BS 6755 to grant their operation suitability in case of fire. Secondary metal to metal seal acts as backup. If primary seal is destroyed by fire. Valves ordered for complaiance with API 607 will be provided with graphite packing and gaskets.Body & Cap

Split or 3-piece, split body & cap for 12" & small. Disassembles easily for repair or replacement of internal components.

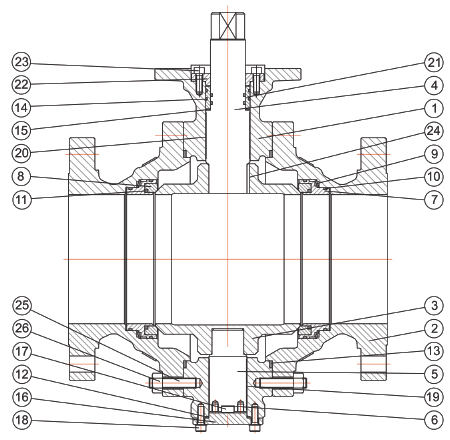

Trunnion Type Ball Valve Material List

| ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

Note 1. Metal seat parts

Note 2. Hard Faced (H/F) - Tungasten carbide, Chromium Carbide, Stellite or others materials.

Note 3. For higHER THAN 600LB only.

Trunnion Type Class 150 LB

|

||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

Trunnion Type Class 300 LB

| ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

Trunnion Type Class 600 LB

| ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

Trunnion Type Class 900 LB

| ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

Trunnion Type Class 1500 / 2500 LB

| ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||